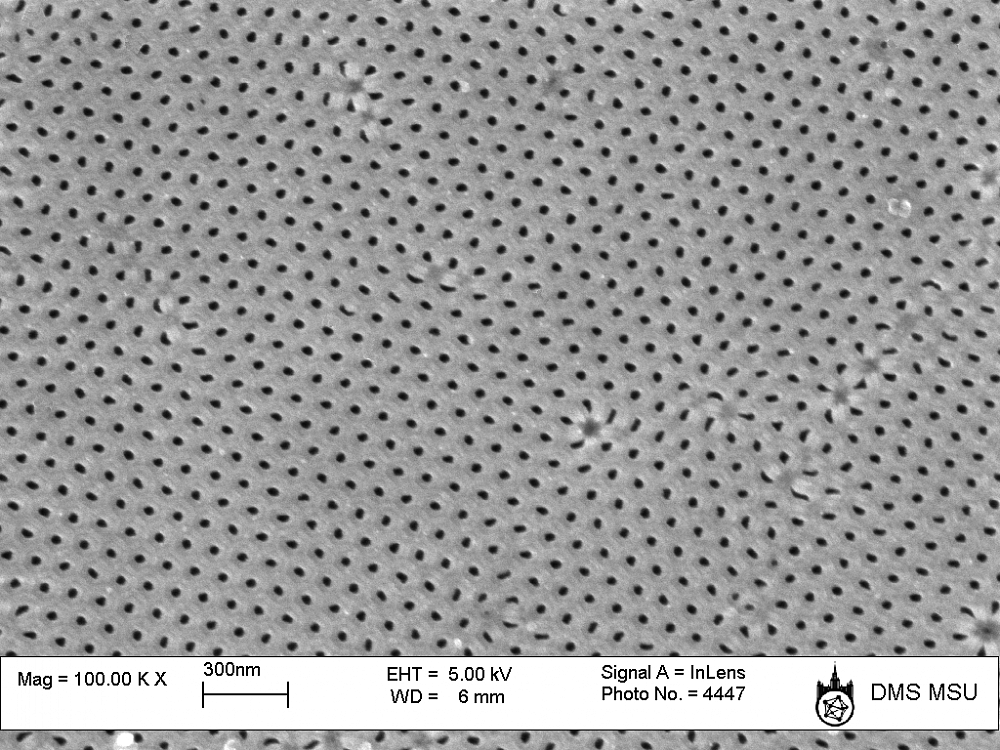

An ideal structure of porous anodic aluminium oxide films can be represented by a system of ordered channels, which are perpendicularly aligned to the aluminium support and form two-dimensional hexagonal framework in the plane of the film. Owing to a great number of studies, it is experimentally established that the ordering of channels occurs only in narrow sets of experimental conditions. Many of the observed features of AAO formation are not theoretically explained yet and the reason for this can be associated with simultaneous influence of several factors on the growth of an oxide film.

In our group, the influence of anodizing conditions as well as the structure of an aluminium support on the process of pore self-ordering in anodic aluminium oxide films is actively studied. Understanding of the ordering mechanism is necessary for transition from empirical retrieval of anodizing conditions to the directed synthesis of porous films with the desired functional properties.

Note, that AAO films with highly ordered structure, not only because of a narrow pore size distribution and extremely high pore density, but also owing to a reduced number of branched and terminated channels in the structure, are advanced materials for the development of highly-permeable ceramic membranes and nanocomposites obtained by templated electrodeposition.

To date, AAO is the basis for the creation of a wide range of nanomaterials and high-technology devices. The examples of AAO applications can be found in the studies devoted to the production of membranes for gas separation and liquid filtration, templates for the formation of one-dimensional nanostructures of different composition and geometry, and supports for gas sensors.